Industrial ultrasonic cleaner

Aircraft parts cleaning

The precision of ultrasound cleaning helps both the manufacturers of the components and MRO centres to satisfy the high-quality requirements and the strict safety standards of the sector.

In a sector where safety is crucial, the equipment offered by TierraTech® is essential to clean of hydraulic systems, heat interchangers, engine pieces, injection pumps, vanes, etc. since it does not damage the materials or modify the dimensions or geometry of the surfaces.

TierraTech® has extensive experience in the aeronautic industry and can offer you the most suitable solution to your requirements.

Graphic industry maintenance

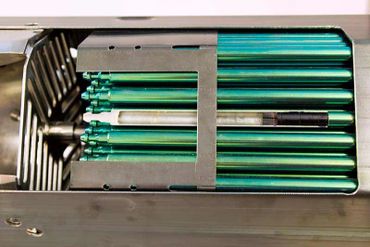

Ultrasound cleaning systems are used to clean rollers and anilox sleeves, etching plates, cartridge holders, ceramic rollers and other removable printing pieces that accumulate oil, water, alcohol or UV-based ink.

The accumulation of dirt causes a progressive deterioration of the drum, which affects the printing quality. The advantages of ultrasound cleaning are the recovery of the transference level of the cells from the anilox rollers (recovery of the cell volume) and also, rotogravure cylinders in all sizes. Ensure a high printing quality by using our machines for your cleaning needs.

Ultrasonic mold cleaning

Immersion washing in our ultrasound tanks is an efficient and high-quality solution to clean all kinds of plastic, rubber, rubber/metal, aluminium injection and zamak injection moulds because they optimise production times.

They also enable cleaning the mould in full without having to dismantle the piece and damaging the parts. This is why this represents the most efficient alternative as opposed to traditional cleaning systems.

We design and manufacture multistage cleaning equipment adjusted to the amount of moulds to be cleaned and the particular needs of the production process to best suit each customer.

Electroplating surface treatment

Ultrasound cleaning before coating the pieces entails saving quite a lot of time and labour. Electroplating surface treatment with ultrasouunds replaces replaces manual cleaning and the long immersion times required by the traditional cleaning methods.

It removes polishing pastes, grease and dirt swift and efficiently from any kinds of metal and plastic pieces, reaching any hidden areas. This means a better adherence to the surface of an electrolytic coating and, therefore, an enhanced appearance and quality of the product.

Ultrasonic paint stripping

Do you want to improve the ultrasonic paint stripping process? In the field of stripping, the use of ultrasounds enables accelerating processes and eliminating all the organic coating from any metallic surfaces. This is why we use the latest generation of strippers.

Strippers combined with the mechanic action of the ultrasounds enables removing paint or coating in full. TierraTech® has ample experience in industrialized stripping processes for steel, aluminum, etc.

We have considerable experience in recovering valuable parts, for example, alloy wheels, automotive components and aluminum profiles for architectural purposes, etc. and in maintaining instruments used in painting lines.

Energy industry maintenance

The energy industry maintenance encompasses sectors such as nuclear, eolian, thermal, cogeneration and solar. We have different solutions adapted to the different sectors, such as cleaning of heat interchanger plates and heads in the nuclear sector.

For the Cogeneration Industry, we decarbonize and degrease engines and clean heat interchangers.

In the Eolian Industry, ultrasounds are used to maintain gear motors.

Food industry cleaning

Our ultrasonic food industry cleaning is ideal to remove oil, greasy dirt, waste and calcareous encrustation.

With the recommended ultrasound system, we achieve a better cleaning result compared to traditional methods.

This constitutes a guarantee for the maintenance of equipment and instruments in an industry with such high hygienic requirements.

Pharmaceutical and laboratory industry

TierraTech pharmaceutical manufacturing equipment.Our ultrasound equipment is used to remove traces of chemical products, oils, pigments or prints, among other residues.

We remove dirt from complex pieces with cracks, hard accesses or joints without damaging them. Ultrasound equipment achieves a superior cleanliness and saves time and effort compared to manual washing.

Ship maintenance

Ship maintenance finds in our ultrasonic cleaning equipment the most suitable option. The Motor Clean range has large capacity equipment, ideal to clean large parts.

The marine sector finds in our ultrasonic cleaning equipment the most suitable option for the maintenance and repair of all types of engines. This is so because ultrasonic cleaning facilitates the cleaning of parts such as heat interchangers, cylinder heads, turbochargers, intercoolers, tube bundles, coolers or propellers and other large and heavy parts; thereby reducing the time and effort involved in the traditional systems.

Ultrasonic parts washing

Ultrasonic cleaning is the most effective solution for parts washing, as well as for industrial bar tuning and piece machining.

It is an excellent solution to clean and remove residue such as shavings, remnants of grease, rust, etc.

Our systems are being implemented in all machining sub-sectors and bar tuning in the ancillary automotive industries, including connections, couplings, implants/medical prosthesis..

Industrial maintenance cleaning

Ultrasonic equipment in industrial maintenance cleaning performs an essential task for the entire manufacturing process.

The harsh working conditions of this type of machinery makes preventive maintenance essential to extend their useful life and ensure smooth operation.

Our ultrasonic cleaning equipment facilitates cleaning chains, gears, electro-valves, transmissions or hydraulic gears, heat interchangers, filters, etc. contributing to a correct maintenance that favors efficient operation of the machinery and reduces the possibility of unexpected breakdowns.

Video

Mold cleaning

Anilox roller cleaning

Cosmetic pharmaceutical industry

Steel cable cleaning

Photo Gallery

- Home

- Solutions & Services

- Machinery & Technologies

- Contact Us

- Injection molding

- Automation

- Auxiliary equipment

- Blenders

- Central Systems

- Vacuum Loaders

- Dryers

- Granulators

- Mould Equipment

- Temperature Controllers

- Water Flow Regulators

- Conveyors

- Process technology

- Injection moulds

- Wittmann 4.0

- Ultrasonic Cleaning Equip

- Industrial spare parts

- Privacy Policy

- Extrusion Lines

- Meech Static Control

- News

Industrial Manufacturing and Processing Machinery

Copyright © 2025 WIBA Baltic SIA - All Rights Reserved.

Design by KrasWeb