Automation

Linear Robots, Sprue Pickers, and Complete Automation Solutions

WITTMANN has realized thousands of demanding applications in the field of automation so far. These have led to optimizing production processes and to improving part quality in every single case.

.webp/:/cr=t:16.67%25,l:0%25,w:100%25,h:66.67%25/rs=w:600,h:300,cg:true)

W9 and WX Series

WITTMANN's most flexible robot line. Offering fixed and moving demolding axis. For all robots additional rotation axes in servo or pneumatic execution can be offered.

Specifications

Execution : Z up to 18,000 mm | Y up to 3,600 mm | X up to 3,000 mm | Payload up to 150 kg

Features: Connection to operator PC | Visualization of movements and processes | Clock cycle of 4 ms (0.004 s) | Up to 12 axes synchronous

3 additional rotation axes can be retrofitted

Sonic Series

The ultra-highspeed robot series has been developed to achieve the fastest part removal times and allows mold-open times of less than 1 second.

Specifications

Execution : Z up to 4,000 mm| Y up to 1,600 mm | X up to 900 mm

Payload up to 7 kg

Features: Optional stacker axis | Optional electrostatic charger on Y-axis Frame for later IML usage | Clock cycle of 4 ms (0.004 s)

Piping inside Y-axis | Max. acceleration: 65 m/s²

Primus Series

Robots built for cost-efficiency for pick & place applications at clamping forces of 20 to 900 t - especially developed by WITTMANN for this purpose of use.

Specifications

Execution: Z up to 6,000 mm | Y up to 2,000 mm

X up to 1,200 mm | Payload from 2 to 20 kg

Features: C-Axis pneumatic (removal side changeable) | A-Axis rotation (pneumatic) | Additional E/A available

Sprue Pickers

For the removal of sprues and parts from the injection molding machine. The solid construction allows fast movement with low vibration for precise removal.

Specifications

Execution: Z up to 95° | Y up to 700 mm | X up to 100 mm | B up to 90°

Features: Venturi vacuum with part monitoring | Parts gripper with 4 suction cups

Customized Solutions

Tandem and Special Robots

Tandem and Special Robots

Special automation Solutions according to the customer's needs. WITTMANN does cover with these solutions stack molds, packaging cells, EOAT needs, control of auxiliary devices and complete automation cells.

Tandem and Special Robots

Tandem and Special Robots

Tandem and Special Robots

Double Y-arm solutions for stack molds

Face-to-face mounting for tandem mold applications

Cantilever arm at Y-axis for side-entry

Clean room package

Packaging

Tandem and Special Robots

Packaging

Take-out and IML applications

Top-entry or side-entry solutions

From 1 up to 6 + 6 cav. parts

Visual inspection by camera systems

EOAT

Standard Production Cells

Packaging

Own QuickChange system with RFID recognition

WSG System (WITTMANN Standard Gripper)

3D printing technology

100% customized EOAT solutions

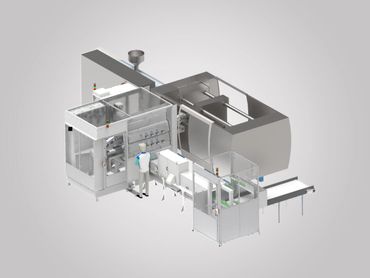

Standard Production Cells

Standard Production Cells

Standard Production Cells

Standard safety housing elements

Space saving

Quick delivery and installation

Complex Customized Cells

Standard Production Cells

Standard Production Cells

Application orientated automation solutions

Integration of different 3rd party components

Worldwide automation centres

Communication to customer network

Photo Gallery

- Home

- Solutions & Services

- Machinery & Technologies

- Contact Us

- Injection molding

- Automation

- Auxiliary equipment

- Blenders

- Central Systems

- Vacuum Loaders

- Dryers

- Granulators

- Mould Equipment

- Temperature Controllers

- Water Flow Regulators

- Conveyors

- Process technology

- Injection moulds

- Wittmann 4.0

- Ultrasonic Cleaning Equip

- Industrial spare parts

- Privacy Policy

- Extrusion Lines

- Meech Static Control

- News

Industrial Manufacturing and Processing Machinery

Copyright © 2025 WIBA Baltic SIA - All Rights Reserved.

Design by KrasWeb